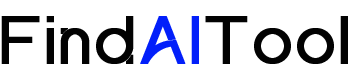

iFactory3D is a pioneering 3D printing technology company that has developed a proprietary belt printer system for automated batch production and long object printing. This innovative technology utilizes a conveyor belt as the building surface and prints at angles of 30 and 45 degrees, enabling continuous production and the creation of exceptionally long objects.

The unique belt printer design offers several advantages over traditional 3D printers. It allows for uninterrupted printing of multiple objects in a single run, significantly enhancing production efficiency. The angled printing capability and conveyor belt system enable the creation of parts with theoretically unlimited length, opening up new possibilities for large-scale 3D printing.

iFactory3D’s technology is particularly suitable for manufacturers, industrial designers, and businesses requiring high-volume production or large-format 3D printing. It caters to industries such as automotive, aerospace, construction, and product design, where the ability to produce long, complex parts or large batches of items is crucial.

By offering automated batch production and the capacity to print oversized objects, iFactory3D brings substantial value to its users. It streamlines manufacturing processes, reduces production time and costs, and enables the creation of parts that were previously challenging or impossible to produce with conventional 3D printers. This technology empowers businesses to enhance their production capabilities, explore new design possibilities, and stay competitive in industries where rapid prototyping and custom manufacturing are essential.